Product Description

DJI Agras T100 Three Battery Combo

Big Drone, Big Jobs.

The T100 Agricultural Drone, a groundbreaking creation twelve years in the making, boasts a maximum payload of 100 kg[1]. Its operational efficiency is doubled, supporting multiple application scenarios, including spraying, spreading, and lifting tasks. Featuring industry-leading safety systems[2] and advanced algorithms, it delivers unparalleled safety performance and an intelligent operational experience.

Spraying System

Efficient operation, Outstanding performance.

The T100 comes equipped with a 100 L tank and dual atomising centrifugal sprinklers, enabling faster flight speeds, wider spray coverage, and higher operation efficiency for large-scale field applications. Orchard users can choose an optional mist sprinkler set, which upgrades flow rates and atomization effects to penetrate dense canopies and reach the undersides of leaves on tall, thickly-canopied trees, ensuring outstanding versatility and performance across various agricultural tasks.

Field Operations

36% Increase in Operation Efficiency [27]

30L/min High Flow Rate

5-13m Effective Spray Width [8]

20m/s Maximum flight speed [6]

Orchard Operations

40L/min Four Sprinklers

25% Increase in Effective Spray Width [7]

65% Increase in Leaf Underside Coverage [7]

Water-Cooled Mist Sprinkler (Optional) – Fine droplets as small as 50 μm[23] penetrate canopies for comprehensive leaf coverage. A new liquid flow path helps dissipate dual centrifugal motor heat for durability and longevity.

Dual Atomization Centrifugal Sprinkler – New flow channel design, particle size range 50-500 μm[9], suitable for most operational scenarios.

Magnetic Drive Impeller Pumps – Corrosion-resistant, stable, and reliable, an optimized impeller structure and increased chamber volume meet the high flow demands of orchard scenarios.

Rear Four Sprinklers Array – It expands the spray width for orchard operations while maintaining uniform coverage. It also minimizes visual interference from mist, enhancing operational reliability and precision.

Dual-Channel Electromagnetic Flow Meter – Real-time precise flow detection and dynamic control ensures high-precision operations. It avoids direct contact with the liquid, preventing corrosion and enhancing durability.

Spreading System

Bigger Loads, Faster Flow, Better Efficiency

The T100 Spreading System has been fully upgraded, with double the load capacity, and a 270%[7] increase in flow rate. Equipped with a brand-new screw feeder, it is suitable for various granulars and can handle spreading scenarios in large fields, orchards, aquaculture, and more.

150L(100kg) High Capacity Spreading Tank[3]

66% Increase in Operation Efficiency[27]

400kg/min Ultra-High Flow Rate[4]

10m Effective Spreading Width[10]

20m/s Maximum flight speed[6]

Brand-New Screw Feeder – Spreading accuracy doubled, flow rate increased by 270%[7], and granulars applicability further enhanced.

High-Precision Weighing Sensor – Provides real-time, accurate display of granular quantity, allowing for precise usage and refilling, effectively minimising waste. Automatic flow rate calibration and cloud-save operation templates, making spreading operation more accurate and convenient.

Centrifugal Spreader Disc – Ensures uniform spreading across the entire flow range with outstanding results. Features a stainless steel cap for durability and strength.

Large Loading Gate – Allows for easy and convenient bulk loading.

Four Feeder Types

Supports four interchangeable feeder sizes for precise flow and greater adaptability[11] across seeding, fertilizing, and feeding.

Extra-Large Feeder

Suitable for granulars such as fertilisers, wheat seeds, granular fungicides, feed, etc.

Recommended application rate: 75-750 kg per hectare.

Recommended particle size: 0.5-10 mm

Large Feeder (Optional)

Suitable for granulars such as rice seeds, cover crop seeds, etc.

Recommended application rate: 75-270 kg per hectare.

Recommended particle size: 4-10 mm

Medium Feeder

Suitable for granulars such as rice seeds.

Recommended application rate: 22.5-120 kg per hectare.

Recommended particle size: 4-6 mm

Small Feeder (Optional)

Suitable for granulars such as rapeseed, granular herbicides, grass seeds, granular insecticides, etc.

Recommended application rate: 3-22.5 kg per hectare.

Recommended particle size: 0.5-4 mm.

Safety System

Industry-Leading Safety System[2], Safer With Every Flight

Omnidirectional Sensing, Precise Obstacle Detection[2]

T100 is equipped with advanced technologies, including a new LiDAR, millimeter-wave radar, and a Penta-Vision system[12]. These features enable comprehensive environmental awareness, allowing for precise obstacle detection.

LiDAR – Capable of capturing dense spatial point cloud up to 300,000 points per second, providing a detailed view of complex terrains.

Millimeter-Wave Radar – The front radar performs 5,000 vertical airspace scans per second combined with 360° horizontal mechanical rotation scanning, along with a rear radar[12] offering a more comprehensive detection range.

Penta-Vision System [2] – The quad-vision system, paired with an FPV low-light full-color camera, facilitates unrestricted viewing of flight scenes in front, behind, left, right, and below, while intelligently identifying obstacles. The FPV camera employs virtual gimbal technology, offering an ultra-wide field of view complemented by stabilization algorithms, to achieve electronic image stabilization for smoother, more fluid footage.

Night Navigation Light [13] – In addition to the existing low beam lights, new front-facing high beams and downward supplemental lighting have been added, ensuring safer nighttime operations.

Smarter Obstacle Bypassing [2]

Obstacle Type Detection [2] – The system can detect various obstacle types, including wires[29], poles, high-voltage towers, and trees. It intelligently selects the optimal path, ensuring smooth and seamless bypassing around obstacles.

Automatic Obstacle Position Memory – The system automatically remembers obstacle locations, enabling more precise bypassing during subsequent flights. Users can save obstacles to a field with a single click, increasing safety with every flight.

Terrain Following Without Mapping – The system can achieve Terrain Following of slopes up to 90° without prior mapping. It also supports intelligent obstacle bypassing[2], addressing the operational requirements of most mountainous and orchard environments with efficiency and precision.

AR Safety Assistance

Real-Time LiDAR Point Cloud Display – Real-time LiDAR point cloud visualization offers clearer and more intuitive obstacle detection compared to FPV. This is especially valuable when dealing with small obstacles or operating at night, ensuring enhanced operational awareness and safety.[2]

AR Display for People, Vehicles, and Obstacles [14] – Detect utility pole and vehicles during takeoff and landing with AR visualization for enhanced safety. During flight, it further enables AR display of obstacle types and distances, ensuring precise and informed operations in real time [14].

AR Flight Route Prompts[14] – The system generates AR flight paths to assist with route guidance, providing enhanced precision and efficiency for every operation.

AR Return-To-Home Projection[14] – AR display of return-to-home point locations and safe landing projections assist with return and landing operations, ensuring greater accuracy and safety for every operation.

Enhanced Obstacle Avoidance Capabilities

With advanced multi-sensor fusion and upgraded algorithms, the T100 achieves a higher success rate in avoiding various obstacles. Its precision in detecting smaller obstacles is significantly improved, ensuring safer and more reliable operations[2].

Lift System

Your Transport Assistant

The T100 transforms into a transport solution. With a lifting maximum capacity of 100 kg[5]. Features like auto balance control , weight detection, and automatic navigation to loading and unloading points make it adaptable to various agricultural transport scenarios.

Auto Balance Control – Utilizing a triaxial force sensor, the drone can automatically adjust its posture during flight to eliminate swinging, ensuring safer operations.

Real-Time Weighing – A triaxial force sensor provides real-time weight monitoring to prevent overloading and ensure operational safety.

Marking Loading and Unloading Points by Mobile – Operators can use their mobile phones, in conjunction with the RTK module, to add load and unload points, which are then synced to the remote controller. Pilots can quickly locate destinations using AR projection on the controller.

Automatic Flight – Freely select loading and unloading points and reach them with a single click.

Upgraded Lifting System – The optional dual battery version has a lifting capacity of 80kg[28], suitable for scenarios requiring long endurance. For extreme situations where hanging cargo gets trapped or tangled, you have the option to heat and cut the cable, freeing the drone.

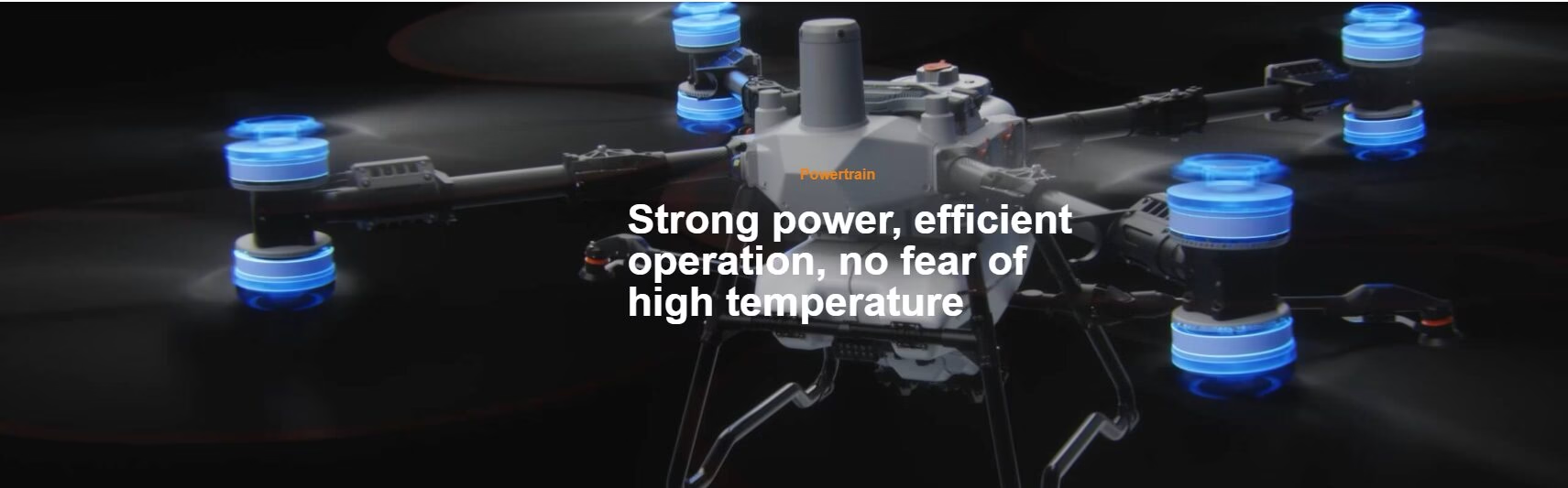

Propulsion System

Powerful, Efficient, Reliable Under High Temperatures

The coaxial dual-rotor design, paired with carbon fiber propellers, delivers a comprehensive upgrade in performance, efficiency, and safety redundancy.

Powerful Performance

82 kg Single-Axis Max Thrust

20 m/s Max Speed[6]

Compact Size, High Load Capacity

Energy Efficiency

39%[7] Increase in Full-Load Power Efficiency

Safety Redundancy

Propeller Stop Protection

Low battery performance under heavy load

Efficient Operations

Increase in Spray Width[15]

Increase in Operation Speed[15]

Enhanced Penetration for Orchards

62-Inch Carbon Fiber Propellers – Carbon fiber propellers offer greater rigidity and lighter weight, resisting deformation even at high temperatures. With optimized airfoil and increased diameter, efficiency is improved by 32%[7].

Motors and ESCs – Larger motors, more torque. 420A electronic speed controllers ensure stable and reliable operation, delivering faster response times.

DJI RC Plus

Easy Control for New and Experienced Pilots

DJI RC Plus features a 7-inch high-brightness screen that is 16%[7] brighter for clear visibility under sunlight. Both internal and external battery life are extended by 30 minutes[7]. New backlit buttons enhance nighttime operation, and customizable physical buttons offer flexible control.

Get Started With Ease for New users

Simply complete the field planning, and operate with one click, without the need for manual intervention.

Step 1: Easy Field Planning – Choose from multiple planning methods. Once the field is planed, the flight path is automatically generated.

Step 2: One-Click Fully Automatic Operation – Easily call up parameter templates with a single click for convenience and speed.

Step 3: Smart Return to Home – Automatically returns home when out of pesticide or low on battery.

Elevate Precision and Efficiency for Experienced Pilots

Experience smooth and intuitive manual operation paired with a range of powerful, efficient assistive features. Tackle even the most challenging terrains with confidence and ease.

Multi Fields Operations – Efficiently plan multiple adjacent plots in a single go. Enabling continuous operations without interruptions (in fields or orchards).

Practical Features for Manual Mode – Simplify operations on complex small plots with practical tools like one-click plot saving and one-click return to breakpoints, ensuring efficient and stress-free workflows.

Free Flight Paths – Adapt effortlessly to diverse scenarios, including mixed crops, intercropping, and paddy fields. Achieve greater operational flexibility for more efficient workflows.

LiDAR Mapping [16] – Mapping up to 20 hectares of large fields or 10 hectares of orchards per flight[17]. The map is reconstructed in real-time on the remote controller, with rapid delivery upon landing[18]. Point cloud density increased, power line detection rate improved by 80%[7].

Rigorous Testing Standards

The T100 has undergone 700 hours of reliability testing, including real-flight aging, accelerated component fatigue, and extreme temperature evaluations. These ensure stability and reliability, delivering unmatched performance under various conditions.

Transmission System

Seamless Signal Stability

The upgraded O4 video transmission algorithm ensures constant signal availabilitys. O4 Relay it’s designed to excel in challenging signal conditions, delivering seamless and efficient operations.

O4 Transmission – An upgraded transmission algorithm enhances the range while maintaining smooth and stable visuals for consistent performance.

D-RTK 3 AG (Optional) – Enabling plug-and-play centimeter-level positioning without the need to configure coordinates. It ensures precision across the entire operation.

RTK High-Precision Positioning Module – Use in conjunction with the remote controller and smartphone for precise location marking.

O4 Relay (Optional) – A Relay can ensure smooth operations in scenarios that have signal interference.

Power System

Ultra-Fast Charging, Energy-Efficient Design

The DB2160 Intelligent Flight Battery has an increased capacity and lighter built, offering ultra fast charging while reducing fuel consumption. Its innovative triple air-channel cooling system disperses heat through airflow, ensuring safe and stable energy management with efficient cooling even during flight.(It varies between countries.)

DB2160 Intelligent Flight Battery

41 Ah

1500 charge cycles under warranty[19]

500 A high-power connector

Weight: 14.7 kg

Ergonomic handle

C10000 Intelligent Power Supply

Single-phase power input

9000 W fast charging[21][22]

Adaptive power protection

1.5 m charging cable

C12000 Intelligent Power Supply

Tri-phase power input

12000 W fast charging[21]

Adaptive power protection

1.8 m charging cable

Notes

*The product is only available in certain countries. The appearance of the product is subject to the actual product. For details, please contact your local dealer.

[1] Measured at sea level, DJI Agriculture App intelligently recommends the appropriate loading weight based on the current status of the aircraft, environmental conditions, and operational tasks. Users are advised not to exceed the recommended maximum weight of the loaded granulars, may impact flight safety.

[2] The effective sensing range and its ability to avoid and bypass obstacles will vary depending on the ambient light, rain, fog, and the material, position, shape, and other properties of the obstacles. Downward sensing is used to assist in Terrain Following flight and altitude stabilization, while other directions assist with obstacle avoidance. Any collision between the bottom of the aircraft and obstacles shall be the customer’s responsibility. In scenarios without linear obstacles, if a collision occurs at speeds up to 13.8 m/s resulting in aircraft damage, responsibility can be determined through log analysis, and the aircraft may be eligible for free warranty if non-human causes are identified. If there are linear obstacles like wires or guy wires on utility poles, please mark them as obstacles; otherwise, failure to bypass them will be the customer’s responsibility.

– Note 1. Downward sensing assists in Terrain Following flight. If the bottom collides with obstacles, it is considered user responsibility. – Note 2. Due to limitations in safety system performance, the aircraft cannot automatically avoid moving objects, and accidents of this nature will be attributed to user responsibility.

[3] Different granular densities vary, and the maximum load should not exceed 100 kilograms.

[4] Measured with compound fertiliser. The maximum flow rate may vary due to differences in granule size, density, and surface smoothness of different fertilisers.

[5] A weight of 100 kg is measured below the triaxial force sensor (including the weight of the sling, and hook). Data was measured at sea level. The DJI Agras app will recommend the payload weight according to the current status and surroundings of the aircraft. When adding materials, the maximum weight should not exceed the recommended value, otherwise flight safety may be compromised. Users must comply with local regulations during operation.

[6] The actual operation speed of the drone is related to the terrain slope; the steeper the slope, the lower the operation speed. The maximum operating speed varies by country and operational mode, and is subject to local regulations and the actual firmware version.

[7] Compared to the Agras T50 drone and its supporting equipment. Test results may vary based on different testing conditions.

[8] The effective spray width of the spraying system depends on the actual working scenario.

[9] The droplet diameter is measured by a laser particle size analyser, with a 50-micron diameter using the DV50 standard.

[10] Measured at an operating height of 3 meters with a spinning disc speed of 1,100 r/min and a uniformity requirement of CV < 30%. Higher disc speeds and flight altitudes increase the spreading width.

[11] Suitable for granulars ranging from 0.5 to 10 mm in size. Clumps, straw, woven bags, and impurities, as well as humidity, density, hardness, and shape, can affect spreading adaptability and precision.

[12] To ensure the radar’s sensing performance is fully utilised, make sure the radar surface is clean before operation. If necessary, wipe and clean it.

[13] Night Navigation Light is only for spraying and spreading payloads.

[14] AR safety assistance features serve only as supplementary hints; operators must confirm the surrounding environment’s safety during operation. Detection performance of sensors such as quad-vision and FPV cameras may vary depending on the ambient light, rain, fog, and the material, position, shape, and other properties of the obstacles.

[15] Compared to the Agras T50 drone during field spraying operations. Test results may vary based on different testing conditions.

[16] Mapping operation needs to work with RTK.

[17] The mapping area refers to the area enclosed by the flight path. Single-flight mapping area is affected by firmware version, starting charge level, mapping type, altitude, wind conditions, field shape, slope, etc. The mapping must be conducted with no payload.

[18] Mapping time for the remote controller depends on firmware version, survey type, and other variables.

[19] Batteries are covered by warranty for up to 1,500 charging cycles or 12 months, whichever ends first.

[20] The output power of the charging station may be affected by altitude and fuel quality.

[21] Power output may vary due to local grid factors such as distance, wire material, and diameter.

[22] When using the C10000 Intelligent Power Supply to charge DB1580 and DB2160 intelligent flight batteries, it requires an adapter cable.

[23] Measured by laser particle size analyser, a 50-micron diameter using the DV75 standard.

[24] Different granular materials have varying densities; the maximum load cannot exceed 70 kilograms.

[25] A weight of 65 kg is measured below the triaxial force sensor (including the weight of the sling, and hook). Data was measured at sea level. The DJI Agras app will recommend the payload weight according to the current status and surroundings of the aircraft. When adding materials, the maximum weight should not exceed the recommended value, otherwise flight safety may be compromised. Users must comply with local regulations during operation.

[26] Different granulars have different densities; the maximum load cannot exceed 25 kilograms.

[27] Compared to the T50 agricultural drone and its associated equipment, the operational speed was 13.8 m/s during the test. Overall efficiency conclusions may vary under different testing conditions.

[28] A weight of 80 kg is measured below the triaxial force sensor (including the weight of the sling and hook). Data was measured at sea level. The DJI Agras app will recommend the payload weight according to the current status and surroundings of the aircraft. When adding materials, the maximum weight should not exceed the recommended value; otherwise, flight safety may be compromised. Users must comply with local regulations during operation.

[29]Linear obstacle detection only supports spraying and spreading payloads.